METHOD CNC

CORE CAPABILITY OVERVIEW

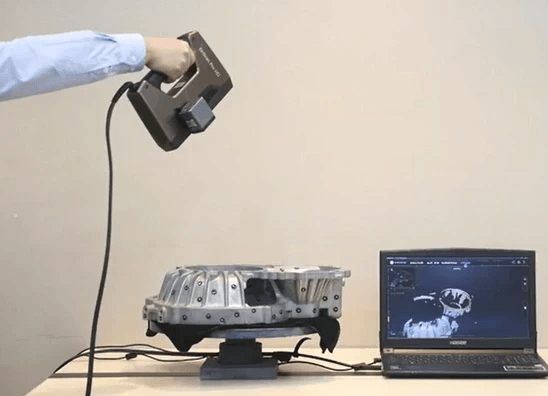

13D SCANNING

HIGH ACCURACY PROFESSIONAL GRADE LASER SCANNER

ONSITE OR WORKSHOP SERVICE

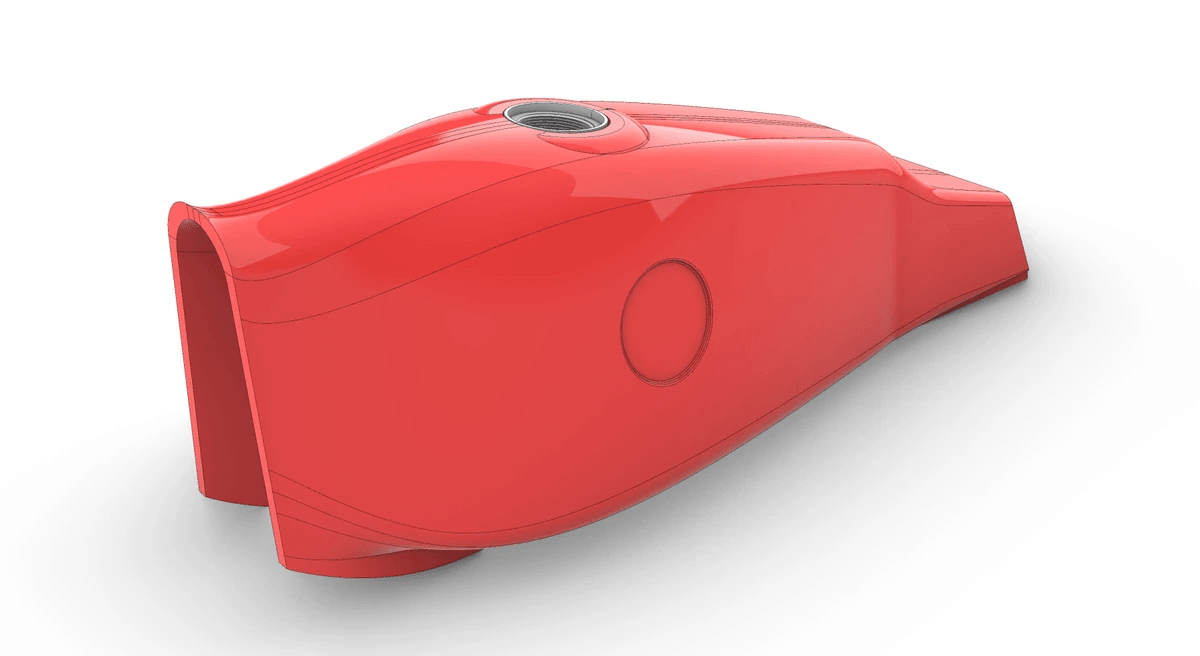

23D DESIGN AND CAD

COMREHENSIVE DESIGN SERVICE

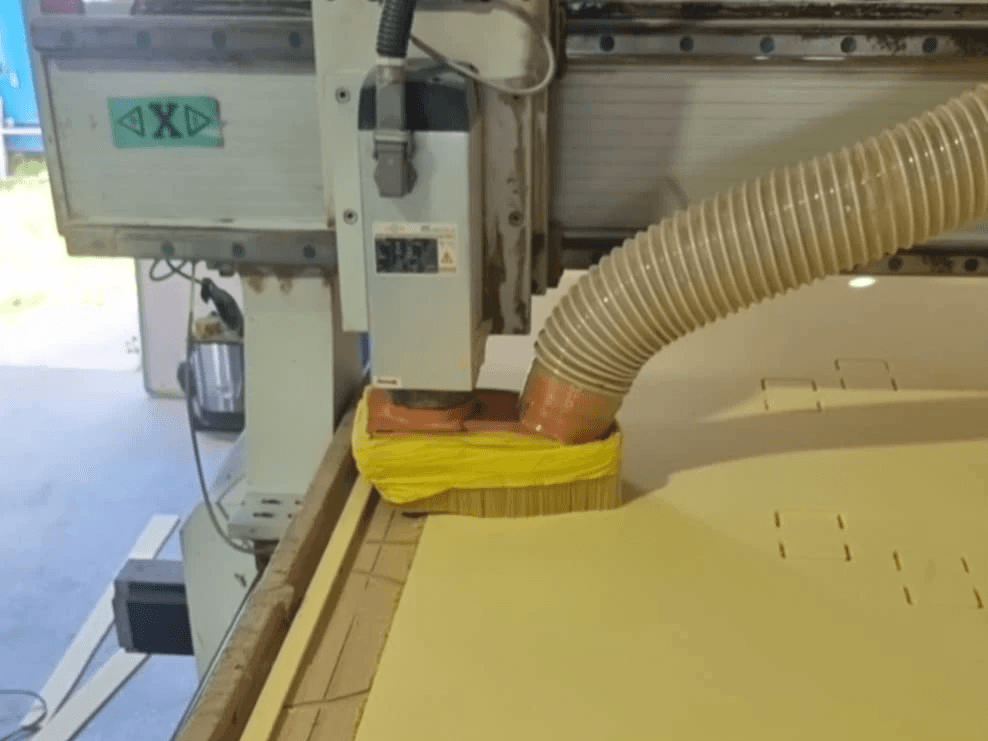

3SHEET CNC MILLING

1200X2400X110

WE CAN CUT PLASTIC SHEETS, PLY, MD AND SOLID TIMBER

4FOAM MILLING CNC

1200X2400X 600

FOAM MILLING

+3D PRINTING

5COMPOSITES FABRICATION

COMPOSITES, TOOLING, CONSTRUCTION AND REPAIR SERVICES

DETAIL OVERVIEW

CNC Machining Flat Sheets

At Method CNC, our full-sheet router (1220x2440mm), combined with advanced programming skills, allows us to create both 2D shapes and intricate 3D forms. We specialize in 2D pocketing, V-carving, rebating, custom angles, and full 3D milled forms. With a wide range of tools and extensive experience in setups and fixtures, we ensure precision and high-quality results. The size of our machine does not limit the scale of projects we can undertake, as we can create bonded milled forms and large-scale jigs to accommodate larger jobs.

We work with Plywood, Hardwoods, Foam

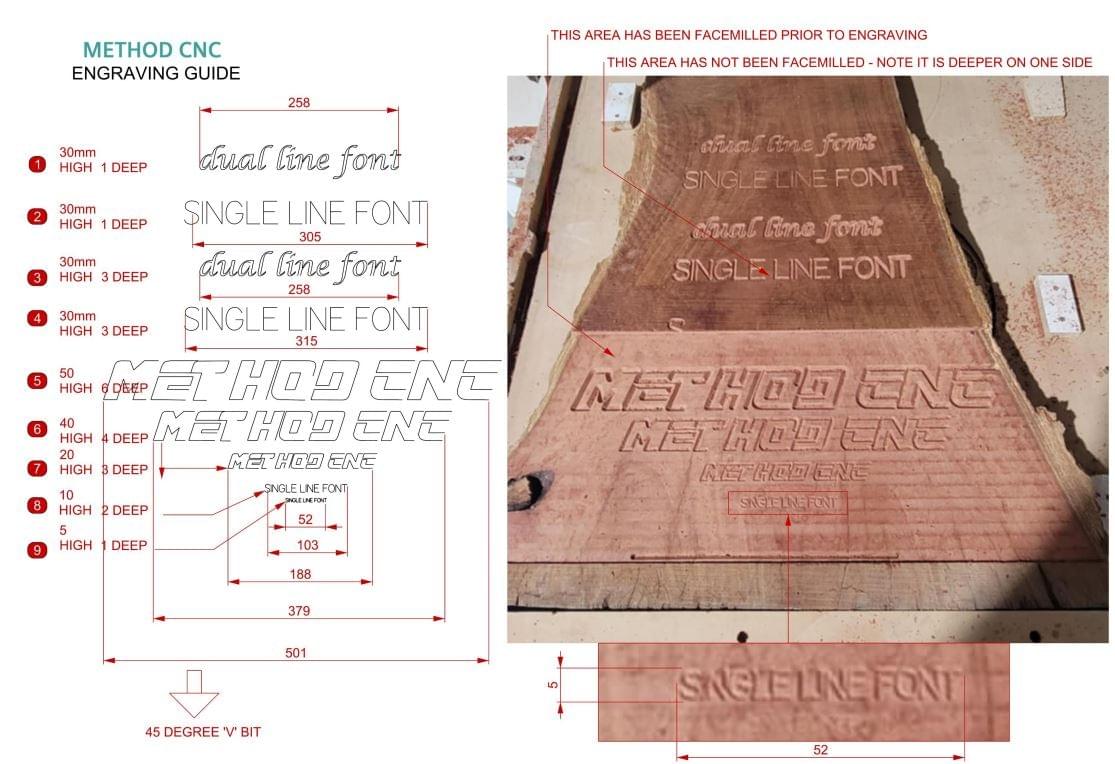

Engraving Timber

We can Mill and Engrave your timber slabs and create signage by using out engraving tools on the CNC see our downloadable engraving guide and reach out with any questions you may have

CNC Machining Foam Milling

At Method CNC, our foam milling router is capable of processing foam up to 600mm high, allowing us to create complex forms with precision. We work with polystyrene, polyurethane, and other foam materials, making it ideal for prototyping, mold creation, and composite fabrication.

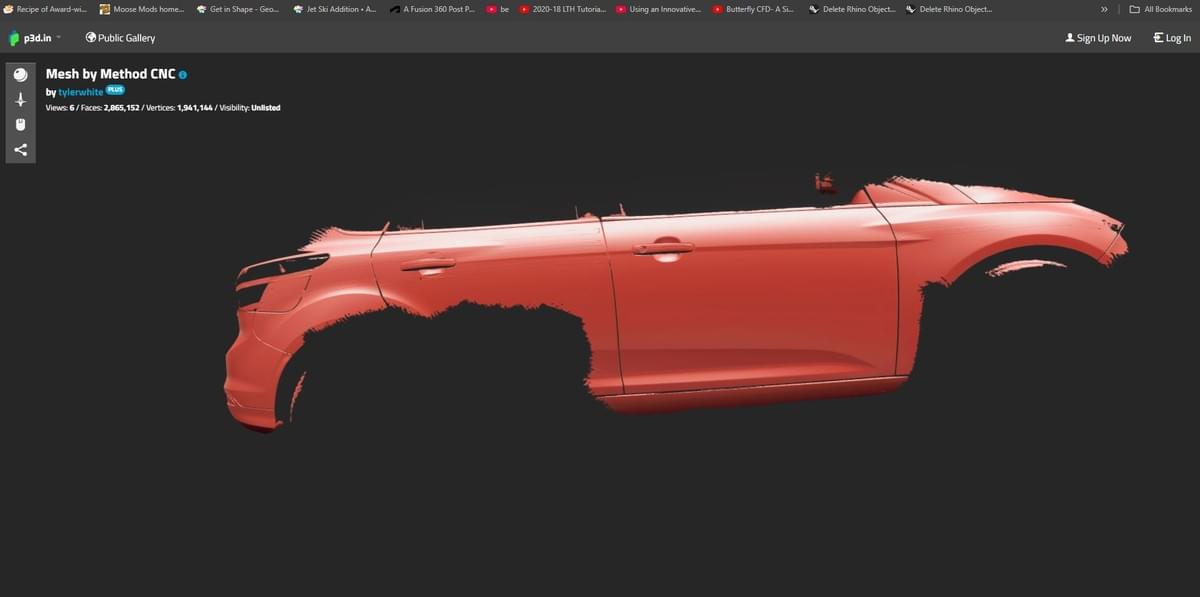

3D SCANNING

At Method CNC, our 3D scanning service offers precise, high-resolution digital replicas of physical objects, enabling accurate reverse engineering, inspection, and modification. Whether for prototyping or custom manufacturing, our advanced scanning technology ensures that every detail is captured with precision and clarity.

Preview our scan data https://p3d.in/FQLg0

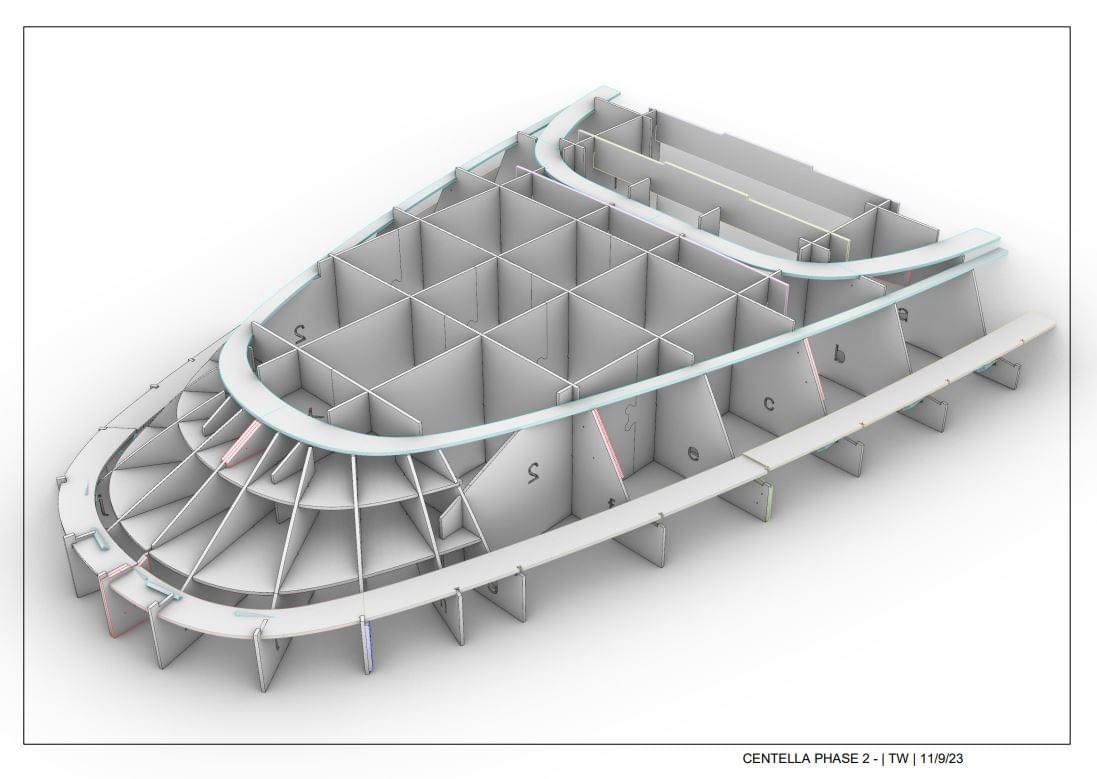

DESIGN AND 3D MODEL CREATION

At Method CNC, we collaborate with Fibre Flow studio, which is a specialist design service offered by Method CNC co owner Tyler White.

We specialize in creating intricate 3D surface models. These models accurately represent the complex forms found in boats, aircraft, automotive designs, and other composite products. Whether starting from scratch or working from scanned data, we leverage advanced digital tools to develop detailed surface models essential for high-precision prototyping, CNC machining, and 3D printing.

3D Printing

At Method CNC, we specialize in creating large, accurate objects from multi-piece 3D prints, ensuring durability and precision. Our expertise goes beyond basic printing—we deliver high-quality, long-lasting components, as well as successful limited-run tools and prototypes. Whether it's for prototyping or production, our advanced 3D printing techniques ensure your designs are brought to life with unmatched accuracy and reliability.

Fibreglass Fabrication

At Method CNC, we collaborate with 26 South Marine, led by Method co-owner Max Marian, to offer a full suite of composite fabrication services. This partnership ensures seamless integration between precision digital design, CNC machining, and expert composite craftsmanship, delivering high-quality results for marine, automotive, aerospace, and custom project

3D SCANNING IN DETAIL

WHAT IS 3D SCANNING?

3D scanning captures the shape and details of an object, creating a high-precision digital mesh for reverse engineering, quality control, and CNC machining.

At Method CNC, we use a commercial grade 3d scanning setup to scan everything from boat hulls to aerofoils with exceptional accuracy. We offer onsite scanning across Brisbane and the Sunshine Coast or in our workshop, with interstate services available by arrangement. Contact us today!

SCAN DATA (MESH) PROCESSING

Once your object is 3D scanned, we can process the mesh data for a range of applications, including:

- Visualization & Digital Inspection – Create high-quality 3D models for presentations, simulations, or virtual prototyping.

- Direct CNC Milling & 3D Printing – Convert scan data into toolpaths for precision machining or additive manufacturing. - (this only works for direct replicas)

- Part Analysis & Quality Control – Compare scanned models to CAD designs, detect deviations, and ensure accuracy.

- Reverse Engineering – Transform scan data into editable CAD files for modifications, upgrades, or reproduction.

Give us a Call or message to find the right solution for your project!

View a Mesh from our Scanner

Follow the link to see a Mesh captured with our scanner to give you an idea of the quality.

We also offer online hosting of mesh data!

How Does it Work

Consulation about your scanning requrements.

Arrive on site / Item arrives at Method CNC Workshop

Confirm object to be scanned -

Confirm Critical areas / details

Apply 3d scanning dots to object

Commence 3d Scanning dots

Commence 3d Scan

Remove 3d Scanning Dots

Generate Mesh from Scan Data

How Does it Work

Consulation about your scanning requrements.

Arrive on site / Item arrives at Method CNC Workshop

Confirm object to be scanned -

Confirm Critical areas / details

Apply 3d scanning dots to object

Commence 3d Scanning dots

Commence 3d Scan

Remove 3d Scanning Dots

Generate Mesh from Scan Data

About us

Formation of Method CNC

Tyler White and Max Marian combine hands-on craftsmanship with advanced digital fabrication expertise to deliver innovative, high-quality solutions. Their collaboration began 15 years ago working together at Noosa Marine and took a pivotal turn two years ago during the creation of a custom orthopedic carbon fiber back support, produced from a 3D scan and CAD model. This project highlighted their complementary skills and led to the formation of Method CNC in early 2024, offering precision CNC machining and services across the marine, art, automotive, furniture, and product design industries.

Carbon Fibre Back Support Project

Max Marian

With over 15 years of experience in boatbuilding and composites, Max Marian has led teams on major custom yacht builds and completed numerous complex refits and rebuilds. Known for his keen eye for detail and expert management of construction, Max blends traditional craftsmanship with a solid understanding of CNC processes. His hands-on experience and technical knowledge ensure that every project—whether a custom yacht or a complex CNC job—is completed with precision and care.

Tyler White

Tyler White is a specialist in digital fabrication for Composites, incorporating 3D modeling, scanning, CNC/robotics programming, and 3D printing. His experience spans the automotive, aerospace, marine industries, and the arts. While he is also a qualified composite technician, his primary focus is on delivering innovative, high-quality designs and manufacturing code that push the limits of CNC and 3d printing3D Design and CAD

In detail

Meet your designer

I’m Tyler White, a 3D scanning and CAD expert with extensive experience across multiple industries—including military, marine, automotive, film, art, and sports. My work often involves plywood, foam, or composite materials, whether it’s cutting a single sheet, scanning a part, or designing complex tooling for large-scale projects.

I specialize in:

- 3D scanning

- CAD modeling

- CNC programming

- Robot programming

- 5-axis milling

- Large-format 3D printing

I’ve served as a draftsman, designer, and programmer, mentored at the University of the Sunshine Coast, and helped several startups establish digital fabrication workflows from scratch.

Today, I’m building Method CNC—where design, fabrication, and hands-on expertise come together to deliver quality outcomes. I collaborate with Max, a master craftsman and trusted partner, to manage projects ranging from quick one-offs to full production runs.

Whether you need a part cut or scanned or you’re planning a complex multi-stage project, we’re here to help. You’ll deal directly with me or Max, and I’ll ensure your file is handled with care from start to finish.

Call: 0451 733 537

Design Consultation

Whatever your project — whether it’s simple cabinetry or a complex kit to create the form of a boat or fibreglass part — it all starts with a quick chat (or an email exchange) where we look at the scope of the job.

Some of the first questions I’ll usually ask are:

Do you have a drawing or a 3D model?- If you already have a drawing and just want us to cut or reproduce something — we can easily take care of that.

- If you have a physical object you'd like to replicate or modify, we might scan it and use that as a starting point.

- If you’ve got a 3D model that’s close but needs some adjustment, I can prep it for CNC machining, fibreglass tooling, or whatever process the job calls for.

- If you have some good reference images or examples of the product you want

There’s always more than one method to get the job done — different materials, milling styles, and fabrication techniques all have their place. This is where the consultation really comes in. Whether we’re talking about foam, plywood, or composite tooling, I’ll help you weigh up the options and pick the method that best suits your design, timeline, and budget.

This process isn’t always about starting from scratch — it’s often about adapting what you already have and making it work in the real world.

When you’re at the beginning of a project, there are always lots of questions — even if it’s just for a single sheet of wood.

Technical

I primarily use Rhino 8, along with a range of powerful plugins including xNURBS, Mesh2Surface, RhinoCAM, and Bongo, for surface modeling and working with 3D scan data. While I occasionally use tools like Autodesk MeshLab and the GOM Inspect suite, Rhino remains my main platform — tried, tested, and proven in the field.

For project management, I use Microsoft Project or Monday.com, depending on the complexity and workflow of the job.

Large file transfers are handled via Dropbox or WeTransfer, and for quick communication during active projects, I use Microsoft Teams or WhatsApp — whatever suits the client best.

For design reviews and sharing updates, I often use unlisted YouTube videos to give clear, visual walkthroughs of progress or feedback points.

For more info see below or visit out website dedicated to our design service - www.fibreflowstudio.com

Design Examples - click on them for more details

Social Media

Contact Us

Don't be afraid to reach out. You + us = awesome.

Shed 6/25 Hill St, Pomona QLD 4568Tyler: 0451733537 Max: 0415 107 208In Depth Details About Our Work:

Before Method CNC was officially formed, Max from 26 South Marine and I worked together on a...SLAB MILLING AND FINE ENGRAVING

DOWNLOAD OUR ENGRAVING GUIDE HERE

The Software we use: