METHOD CNC

CORE CAPABILITY OVERVIEW

13D SCANNING

HIGH ACCURACY PROFESSIONAL GRADE LASER SCANNER

ONSITE OR WORKSHOP SERVICE

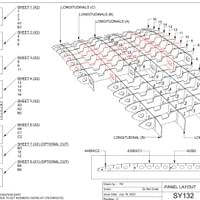

23D DESIGN AND CAD

COMREHENSIVE DESIGN SERVICE

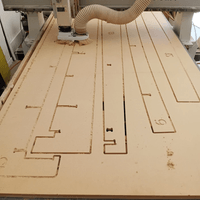

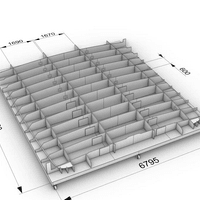

3SHEET CNC MILLING

1200X2400X110

WE CAN CUT PLASTIC SHEETS, PLY, MDF AND SOLID TIMBER

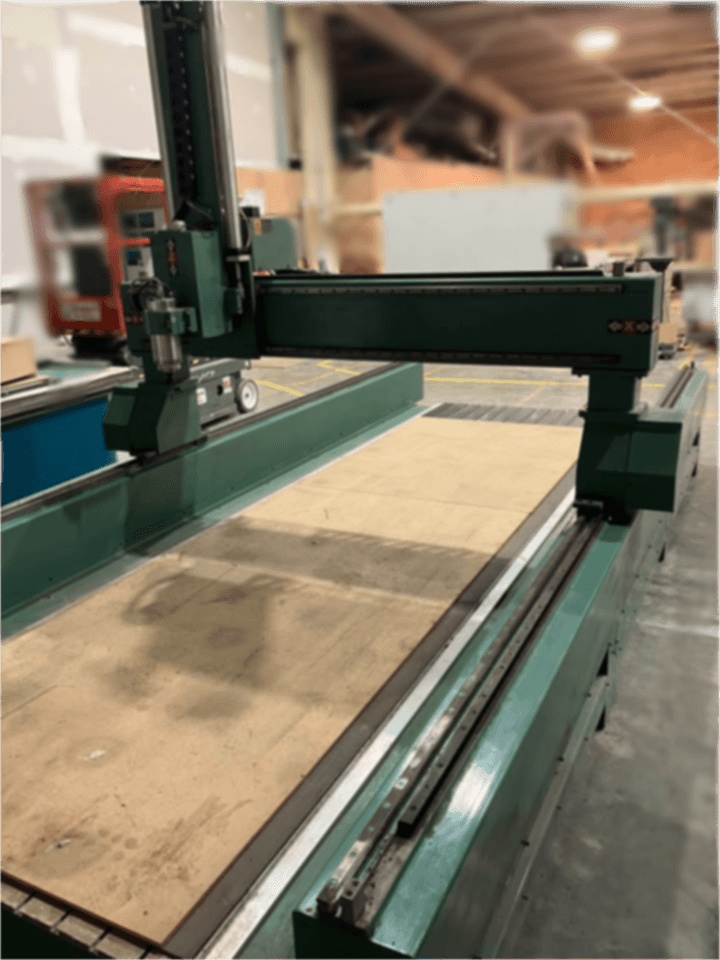

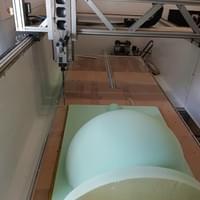

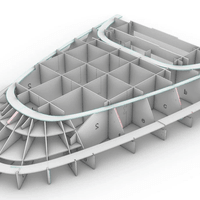

4FOAM MILLING CNC

4000x1200x700

4 axis

FOAM MILLING

+3D PRINTING

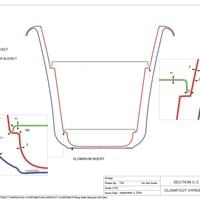

5COMPOSITES FABRICATION

COMPOSITES, TOOLING, CONSTRUCTION AND REPAIR SERVICES

DETAIL OVERVIEW

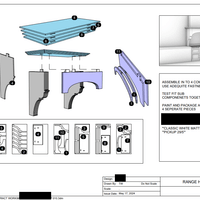

Large Scale 3D Milling

Our 4-axis CNC machine processes foam, wood, and tooling materials with a cutting envelope of up to 4 m × 1.3 m × 700 mm, delivering finishes from off-the-mill to high-gloss, tooling-ready surfaces.

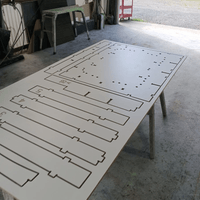

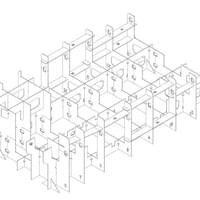

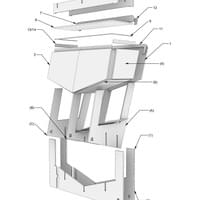

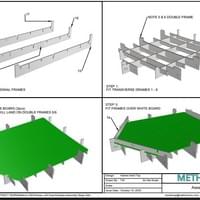

CNC Machining Flat Sheets

Our full-sheet CNC router (1220 × 2440 mm) produces precise 2D and complex 3D forms, including pocketing, V-carving, rebating, custom angles, and full 3D milling. We also produce bonded large-scale forms and jigs beyond single-sheet limits.

Materials: Plywood, hardwoods, foam

3D SCANNING

Our 3D scanning service delivers high-resolution digital replicas for accurate reverse engineering, inspection, and modification, supporting prototyping and custom manufacturing.

Preview scan data: https://p3d.in/FQLg0

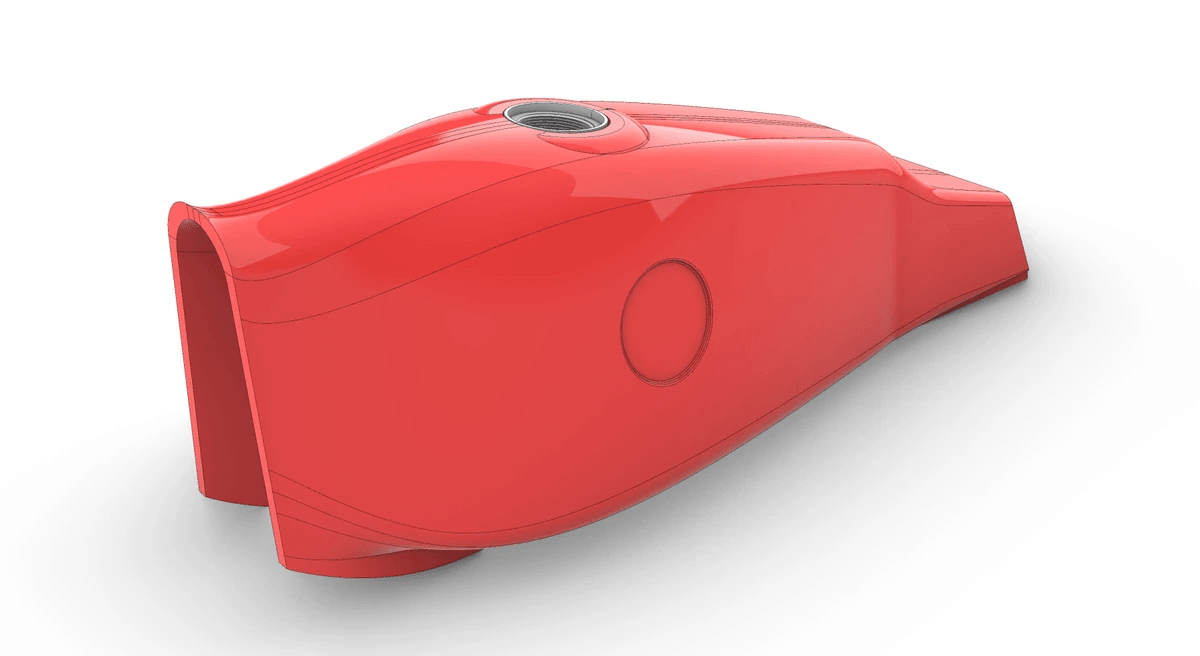

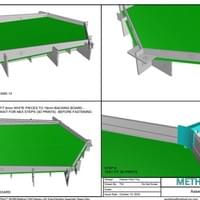

DESIGN AND 3D MODEL CREATION

We create high-accuracy 3D surface models for complex composite forms, supporting precision prototyping, CNC machining, and 3D printing—from concept or scanned data.

Experience: 15+ years CAD for composites

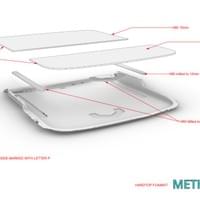

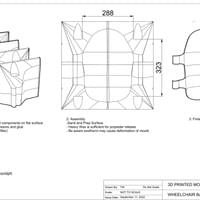

3D Printing

Method CNC produces large, accurate components using advanced multi-piece 3D printing. We deliver durable prototypes, tooling, and limited-run parts with high precision and reliability.

Capability: 3 × Bambu Lab 3D printers

Fibreglass and Carbon Fibre Fabrication

Method CNC incorporates the 26 South Marine composites business, bringing together skilled tradespeople and advanced manufacturing capability. This integrated approach aligns precision digital design, CNC machining, and expert composite craftsmanship to deliver high-quality solutions across marine, automotive, aerospace, and custom projects.

About us

Tyler White and Max Marian combine traditional composite craftsmanship with advanced digital fabrication to deliver high-quality composite solutions. Together, they bring over 30 years of experience across marine, automotive, aviation, and advanced composites.

Working together for over 15 years, their complementary skill sets—hands-on composite manufacturing and modern CNC-driven workflows—led to the formation of Method CNC, now merged with 26 South Marine. The business delivers precision CNC machining and advanced composite manufacturing across multiple industries.

Max Marian brings deep hands-on expertise in boatbuilding and advanced composites, including vacuum bagging and resin infusion, supported by nearly two decades of industry experience.

Tyler White specialises in digital fabrication for composites, spanning CAD, 3D scanning, CNC machining, and robotic programming.Contact Us

Shed 6/25 Hill St, Pomona QLD 4568Tyler: 0451733537 Max: 0415 107 208