METHOD CNC

CORE CAPABILITY OVERVIEW

13D SCANNING

HIGH ACCURACY PROFESSIONAL GRADE LASER SCANNER

ONSITE OR WORKSHOP SERVICE

23D DESIGN AND CAD

COMREHENSIVE DESIGN SERVICE

3SHEET CNC MILLING

1200X2400X110

WE CAN CUT PLASTIC SHEETS, PLY, MDF AND SOLID TIMBER

4FOAM MILLING CNC

4000x1200x700

4 axis

FOAM MILLING

+3D PRINTING

5COMPOSITES FABRICATION

COMPOSITES, TOOLING, CONSTRUCTION AND REPAIR SERVICES

DETAIL OVERVIEW

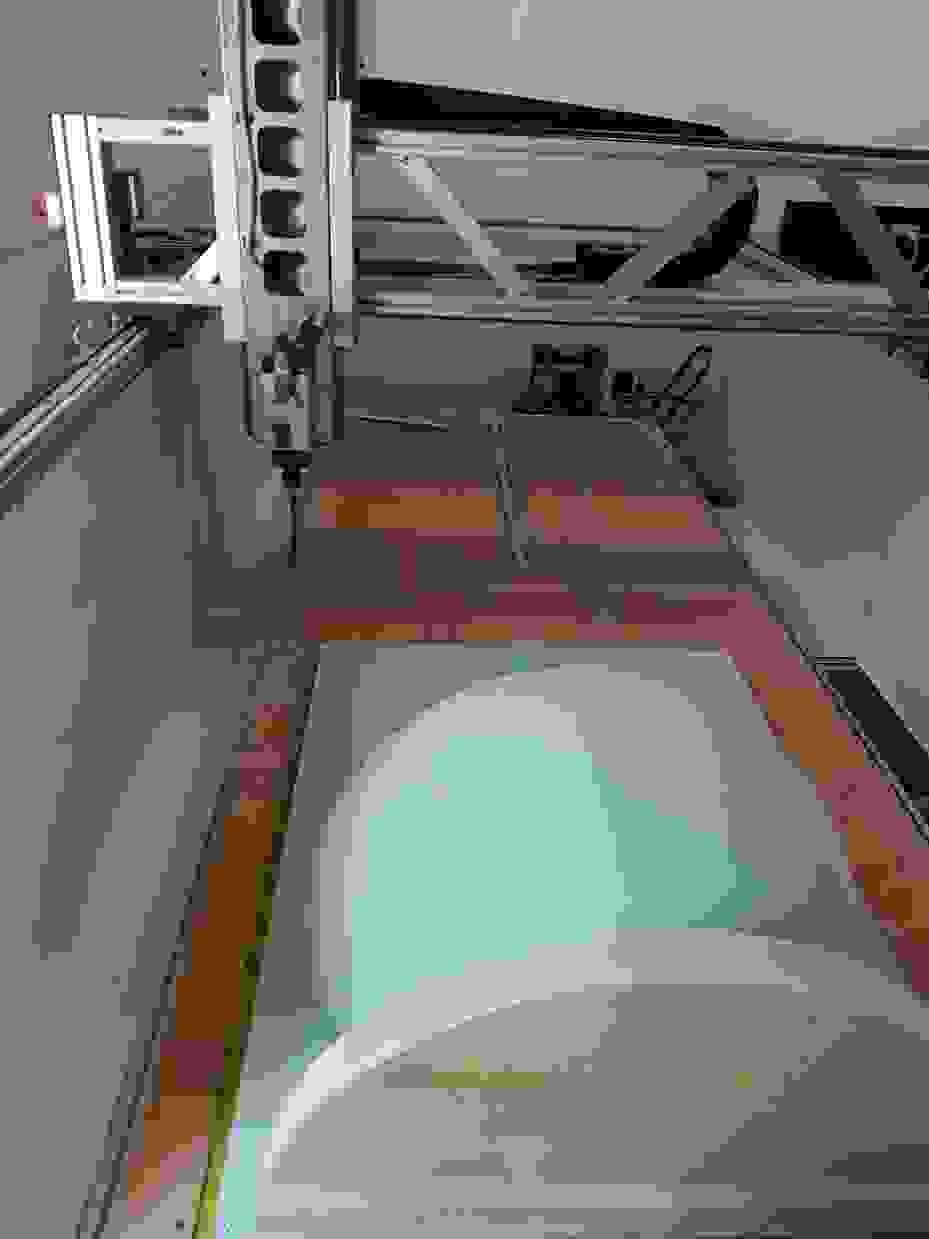

Large Scale 3D Milling

At Method CNC, our 4 Axis CNC is capable of processing foam, wood and tooling materials with a cutting volume of 4m Long - 1.3m wide - 700mm High

CNC Machining Flat Sheets

At Method CNC, our full-sheet router (1220x2440mm), combined with advanced programming skills, allows us to create both 2D shapes and intricate 3D forms. We specialize in 2D pocketing, V-carving, rebating, custom angles, and full 3D milled forms. With a wide range of tools and extensive experience in setups and fixtures, we ensure precision and high-quality results. The size of our machine does not limit the scale of projects we can undertake, as we can create bonded milled forms and large-scale jigs to accommodate larger jobs.

We work with Plywood, Hardwoods, Foam

3D SCANNING

At Method CNC, our 3D scanning service offers precise, high-resolution digital replicas of physical objects, enabling accurate reverse engineering, inspection, and modification. Whether for prototyping or custom manufacturing, our advanced scanning technology ensures that every detail is captured with precision and clarity.

Preview our scan data https://p3d.in/FQLg0

DESIGN AND 3D MODEL CREATION

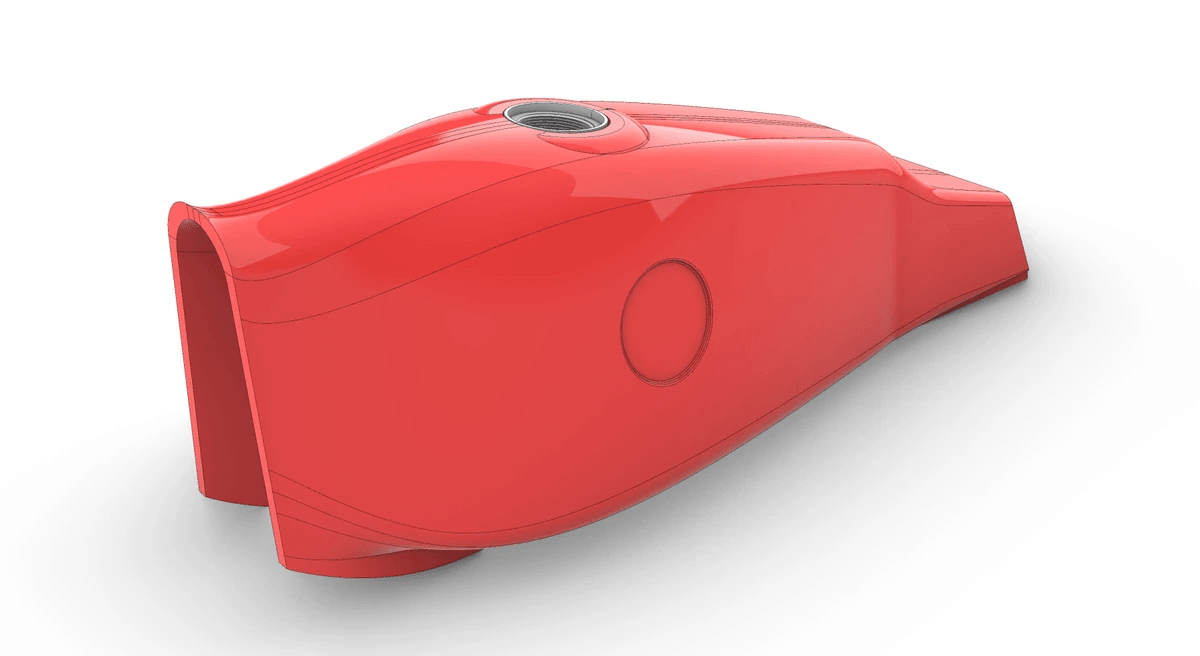

We specialize in creating intricate 3D surface models. These models accurately represent the complex forms found in boats, aircraft, automotive designs, and other composite products. Whether starting from scratch or working from scanned data, we leverage advanced digital tools to develop detailed surface models essential for high-precision prototyping, CNC machining, and 3D printing.

Over 15 years Cad for Composites experience

3D Printing

At Method CNC, we specialize in creating large, accurate objects from multi-piece 3D prints, ensuring durability and precision. Our expertise goes beyond basic printing—we deliver high-quality, long-lasting components, as well as successful limited-run tools and prototypes. Whether it's for prototyping or production, our advanced 3D printing techniques ensure your designs are brought to life with unmatched accuracy and reliability.

Capability - 3x Bambu Labs printers

Fibreglass and Carbon Fibre Fabrication

Method CNC incorporates the 26 South Marine composites business, supported by a team of skilled tradespeople experienced in the manufacture of fibreglass and carbon-fibre components. This integrated structure ensures seamless alignment between precision digital design, CNC machining, and expert composite craftsmanship, delivering high-quality results across marine, automotive, aerospace, and custom projects.

About us

Tyler White and Max Marian combine hands-on craftsmanship with advanced digital fabrication expertise to deliver innovative, high-quality composite solutions. Together, they bring over 30 years of combined industry experience across the marine, automotive, aviation, and advanced composites sectors.

Their collaboration began 15 years ago while working together at Noosa Marine and took a pivotal turn two years ago when they reunited to work side by side on a custom orthopaedic carbon-fibre back support, produced from a 3D scan and CAD model. This project highlighted their complementary skill sets—blending traditional composite craftsmanship with advanced digital design and manufacturing—and led to the formation of Method CNC in early 2024. Today, Method CNC provides precision CNC machining and composite manufacturing services across a wide range of industries.

Max Marian

With over 19 years of experience in boatbuilding and composites, Max Marian has led teams on major custom yacht builds and completed numerous complex refits and rebuilds. Known for his keen eye for detail and expert management of construction, Max blends traditional craftsmanship with a solid understanding of CNC and digital processes. His hands-on experience and technical knowledge ensure that every project—whether a custom yacht or a complex CNC job—is completed with precision and care. Max holds a Cert III in marine craft construction (Boat Builder)

Tyler White

Tyler White is a specialist in digital fabrication for composites, with expertise in 3D modelling, 3D scanning, 3D printing, CNC machining, and Robotic programming. With over 17 years of experience in the composites industry, his background is primarily focused on digital side supported by hands-on workshop experience. Tyler has worked in the composites field across aviaton, automotive and marine projects and holds a Cert III in composites (composite technician) and a diploma in project management.

Timeline

September 2020 26 South Marine Established

April 2025 Method CNC Pty Ltd Established

Jan 2026 Method CNC acquires 26 South Marine

Contact Us

Don't be afraid to reach out. You + us = awesome.

Shed 6/25 Hill St, Pomona QLD 4568Tyler: 0451733537 Max: 0415 107 208